Belles Montres 2014

Interview with Tim Grönefeld

Frederic Dru: Tim, can you tell us a few words about Grönefeld Exclusive Timepieces?

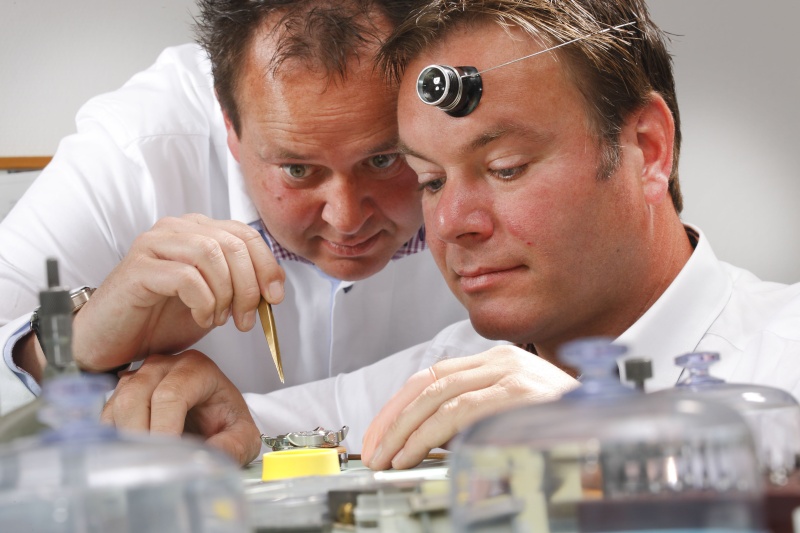

Tim Grönefeld: The Grönefeld family has a watchmaking history spanning over more than a century, the foundations of which were established in 1912 by Johan Grönefeld. My brother and I are now the third generation of Grönefelds.

FD: What is the purpose of Grönefeld?

TG: Bart and I want to build the most exclusive, mechanical timepieces that belong to the best and most complicated in the world. Our timepieces stand for their technical features, the clarity of their design and the excellence of their craftsmanship.

Our success story started in 2008 with our first watch, the GTM-06 tourbillon minute repeater. It was followed two years later by our One Hertz, resurrecting the complication of independent dead seconds. The Grönefeld Parallax Tourbillon, featuring a flying tourbillon, synchronized seconds and in-house calibre G-03 movement, was launched this year.

FD: what about the actual team?

TG: Tim and I are in charge of designing and assembling our timepieces, as well as marketing. In order to provide the best possible quality, we rely on our team, consisting in 10 watchmakers in our production workshop in Holland.

We are first designing our timepieces, and submit it to Renaud et Papi. It takes roughly a year to provide 3D rendering of a new model.

We then receive raw movements, and all decoration work in made internally.

We create around 40 pieces every year.

TG: This was a massive surprise to us. The GPHG prize is considered the « Oscars » of Watchmaking. Actually, we were so surprized at it that we had absolutely no acceptance speech, we just improvized our thanks for this prize! All of a sudden we had a lot of interest from the Horological world, and had many requests from the media. Of course, this was of course a huge focus on our Parralax model, we recently received 35 orders for it.

FD: Who are your customers?

TG: In the beginning of Grönefeld Exclusive Timepieces, our customers were mainly from Holland. This has changed a lot, we now have customers across the world, expecially in Asia. By the way, we are attending a private customers meeting in Singapore next week.

FD: Where do you see yourself in 10 years?

TG: At the exact same place as we are today!!! We are living an extraordinary adventure, and we don’t expect to build more thant 100 timepieces every year.

The Grönefeld Parallax Tourbillon features a « flying » tourbillon with a large central seconds hand, stop seconds, a power reserve- and winding-setting mechanism indicator. The in-house movement displays sophistication and craftsmanship at the very highest level.

Well-designed and impeccably executed tourbillons are particularly accurate timepieces. The tourbillon is a circular cage encompassing the oscillating balance wheel, the beating heart of the movement. The cage rotates once a minute around its axis, minimizing the negative influence of gravity, and consequently improving the timekeeping of the watch.

Invented in 1795 by Abraham Louis Breguet to compensate the effects of gravity on the balance, the tourbillon still continues to be counted as one of the most ingenious complications in watchmaking. In 1920 Alfred Helwig further developed the tourbillon, removing the necessity for an upper support bridge to create a « flying » tourbillon. The absence of the upper bridge enables uninterrupted views to the fascinating mechanism.

The flying tourbillon allows full appreciation of the concentric, rhythmic « breathing » of the balance hairspring, while ensuring high precision. Bart and Tim Grönefeld further highlighted the tourbillon by raising it out of the movement and above the dial. As with the immaculately finished movement bridges, the tourbillon cage is crafted in stainless steel. Three days are required just for the hand finishing of the tourbillon components.

Large central seconds

The large central seconds hand evidences the precision of the Parallax Tourbillon. Normally a central seconds hand requires a friction spring to prevent small fluttering caused by play in the gear train. For the Parallax Tourbillon, the Grönefeld brothers developed the movement with an added pinion and wheel so that the energy-sapping friction spring is not required. A feature improving power transfer to the regulator and contributing to the impressive power-72-hour power reserve.

The name « Parallax » is derived from the precision of the readability of the central seconds hand. Parallax is defined as the apparent change in position of an object when the observer changes his own position. To minimize the possibility of error due to parallax when viewing the seconds hand from an angle, the hand is exceptionally close to the outer chapter ring with the seconds indexes. In a neat addition, the one-armed balance wheel bridge always runs parallel to the central seconds hand.

Push-only crown and function indicator

In addition to the flying tourbillon and friction-spring-free central seconds, the Parallax Tourbillon has yet another innovative feature: rather than pulling the crown to set the time, which has the risk of damaging the fragile crown stem, it is pressed. An indicator on the dial displays the function selected: « W » for Winding or « S » for time setting. When the time setting function is selected, both tourbillon cage-bridge and the central seconds hand automatically return to their respective 12 o’clock positions and stop (or hack) while the time is set.

The ability to set the time to the exact second makes the Parallax Tourbillon potentially more accurate then the vast majority of tourbillons on the market today. Once the time is set and the function set to winding by a simple press of the crown, both the seconds hand and tourbillon cage start running simultaneously and in parallel.

Solid silver dial

The solid-silver dial of the Parallax Tourbillon is composed of seven individual components. The polished beveled edges of the segments mirror those of the stainless steel movement bridges, which are visible through the display back. The bevels are polished with diamond paste to a brilliant gloss and create scintillating reflections of light. Flame-blued steel hands for the hours, minutes and seconds ensure that the time is as legible as it is precise.

Stainless steel bridges

Bart and Tim Grönefeld only use stainless steel bridges for their movements. As well as the superior hardness and durability of stainless steel compared to the more generally used steel and brass, the metal absolutely gleams when polished to a mirror finish. And as stainless steel does not oxidize, the gleaming finish lasts and lasts. However, achieving superlative finishes in stainless steel is no easy task: polishing the hard metal takes a master watchmaker up to four times longer than more commonly used brass. But the Grönefeld brothers feel that effort is well worthwhile and watch aficionados are sure to appreciate the eye-catching effect.

Exclusivity

The Parallax Tourbillon is available in a red gold or stainless steel case 43mm case. Ensuring the exclusivity of this exceptional timepiece, the red gold model is a limited edition of 28 pieces and the « 1912 » stainless steel model is a limited edition of just 12 pieces.

The Parallax 1912 is a limited edition of 12 pieces in stainless steel

Features and indications

Flying one minute Tourbillon

Hours and minutes

Central seconds

Power reserve and Winding-Setting indicator

Innovative Winding-Setting Mechanism with Hacking Seconds

In-house caliber G-03

Case and dial

Case material: Stainless Steel 316L(4335) or Au750 red gold

Engraving 1912: 1912 and individual number in relief. Limited 12 pieces. Stainless steel security screws

Engraving RG: Parallax and individual number in relief. Limited 28 pieces. Serial number. Gold security screws

Case dimensions: 43 mm x 12.5 mm

Sapphire crystals: Top domed with anti-reflective treatment both sides; flat display back with antireflective treatment on both sides

Water resistance: 3atm/30m/100 feet

Crown: Steel or gold with engraved “G” logo and push to set/wind function

Dial: Solid Sterling Silver 925, Frosted surface with diamond cut bevels. Hours- Minutes dial, power reserve indicator, setting-winding indicator. Raised seconds dial to minimalize a parallax error

Hands: Flame-blued steel extended Lancette hands and hand polished centers. Large counter poised seconds hand

Strap and buckle: Hand-sewn matte blue or brown alligator leather and steel or gold tang buckle with engraved Grönefeld logo

Movement

Caliber G-03: Mechanical hand winding, flying one-minute stainless steel tourbillon, power-reserve indicator, hacking seconds and setting mechanism indicator.

Dimensions: 34mm (15 1/4 ’’’) x 9.5 mm

Number of parts: 278

Number of jewels: 27 jewels set in solid gold chatons

Power reserve: 72 hours

Balance wheel: 10 mm free sprung balance wheel Balance frequency: 21’600 vph / 3Hz

Balance spring: Phillips terminal over-coil curve, Geneva-style stud. ELINVAR spring by Nivarox®

Escapement: Straight Swiss lever escapement

Main Plate: Hand spotted rhodium-plated nickel silver

Bridges: Stainless steel and beveled an polished by hand, micro-blasted, circular grain on the top, relief engraved on micro blasted surface

Winding-Setting mechanism: Push function crown for selecting winding or setting

Power reserve mechanism: Classic Breguet style by means of a cone moving up and down on the threaded barrel arbor

With dead seconds – secondes mortes in French – the seconds hand advances in full steps of one second instead of the usual smooth sweeping action of mechanical seconds. Dead seconds was a very respected mechanical complication because it denoted superlative accuracy. However, the popularity of dead seconds faded in the 1970s and 80s with the dominance of quartz movements, which also stepped in full seconds. Mechanical movements soon became distinguished by a smooth, sweeping seconds hand.

With the One Hertz, Bart and Tim Grönefeld have resurrected the long-neglected horological complication of dead seconds and re-positioned it on the pedestal of high precision. The Grönefeld One Hertz is unique among wristwatches in that its dead seconds are powered by a secondary gear train, which is completely independent of the gear train for the hour and minute indications. Until the arrival of the One Hertz, dead seconds was usually derived from constant force devices.

The large seconds hand of the One Hertz subtly signals its unique mechanism, imperceptible to most, but obvious to haute horlogerie connoisseurs who will appreciate the flawless hand-finishing of all 285 components of the calibre G-02, Grönefeld’s own proprietary movement.

The dial is crafted out of solid sterling silver then blasted with brass particles to attain a frosted finish with a very slight sparkle. A thin layer of transparent lacquer is then applied to prevent tarnishing. The soft sheen contrasts superbly with the flamed-blued hands, making for excellent legibility. The graceful arcs and curves of the displays are complemented by the three-dimensionality of the multi-layered dial. The ensemble is beautifully framed by the highly-polished red gold case and bezel.

All applied dial elements, including the dead seconds chapter ring, are rhodium plated with circular graining and beveled edges. The bevels are polished with diamond paste to a brilliant gloss, creating scintillating reflections of light echoing the high-end finishing of the stainless steel movement bridges visible through the display back.

The One Hertz is a prize-winning timepiece. It was awarded the Innovation prize in the 0024 WatchWorld Watch of the Year contest and was voted Watch of the Year by members of the influential watch forum Timezone.

The One Hertz RG is available in a 43mm red gold case.

History of Dead Seconds

With the introduction of the pendulum in the 17th century, clocks finally became accurate enough to measure seconds. It was not long before a hand indicating seconds on a long clock’s dial signified a precision timepiece. A pendulum with a period – the time to swing forward and back – of two seconds (the most common) resulted in a single tick per second.

The invention of the balance spring, which replaced the pendulum, enabled miniaturisation. As portable pocket watches became more accurate, watchmakers naturally thought to copy the one-second steps of the seconds hand which signified a precision timepiece. However, the rapidly oscillating balance meant that it could not be directly driven as with the pendulum, so it required either a new mechanism if independent, or be driven from another complication. While pocket watches have featured independent dead seconds in the past, the Grönefeld One Hertz was the first series wristwatch to feature independent dead seconds. The Grönefeld One Hertz is unique among wristwatches in that its dead seconds are powered by a secondary gear train, independent of the gear train for the hour and minute indications.

“One Hertz”

The hertz (symbol: Hz) is the SI unit of frequency defined as the number of cycles per second of a periodic phenomenon. This SI unit is named after Heinrich Hertz. One Hertz simply means “one cycle per second”. The second (SI symbol: s), sometimes abbreviated sec., is the name of a unit of time, and is the international base unit of time. To highlight the SI seconds, the One Hertz displays dead seconds with a large seconds hand in its own dial. Hours and minutes are non-SI units of time because they do not use the decimal system so are displayed separately.

Mechanical wristwatch movements often have balance frequencies of 2.5 to 5 hertz, which results in the seconds hand making tiny steps of 5 to 10 steps each second and looking like a smooth movement. The seconds hand of the One Hertz is either stationary (dead) or jumping in a full one-second increment each second.

The Grönefeld One Hertz independent dead seconds complication

In a dead seconds complication, friction of the mechanism has to be absolutely minimal so it does not interfere with the escapement and timing. For the One Hertz, Bart and Tim Grönefeld developed an independent dead seconds mechanism that is driven from its own secondary gear train with its own independent power supply. The dead seconds are driven from one mainspring barrel and the hours and minutes from another. With virtually no adverse influence on the escapement this low-friction system lends itself to a highly-precise timing rate.

The two mainspring barrels are wound simultaneously from the crown, which features an innovative “push to set”, “push to wind function”, with the mode selected indicated at 3 o’clock. A power reserve indicator at the top of the dead seconds dial keeps track of the 72 hours of autonomy.

The One Hertz RG is available in a 43mm 5N red gold case.

Independent Deadbeat Seconds

Power-Reserve Indicator and Setting Mechanism Indicator

Technical Specifications Caliber G-02

Movement dimensions

Diameter: 15 1/4 ’’’, 34 mm

Thickness: 9.5 mm

Number of parts Complete movement: 285 parts

Number of jewels : 39 jewels in gold chatons

Power reserve : 72 hours

Barrels : 2 barrels, one for the going geartrain and one for the independent deadbeat seconds mechanism ; Both Barrels are wound at the same speed and in the same direction

Balance wheel : Free sprung variable inertia balance wheel (9.12 mm diameter)

Frequency : 21’600 vibrations/hour

Balance spring : Phillips terminal overcoil curve – Triangle-style stud

Escapement : Swiss lever escapement

Main Plate : Spotted and snailed rhodium plated nickel silver

Bridges : Stainless steel hand beveled, micro-blasted centre and the underneath spotted – Circular grain on the top – Relief engraved in the micro blasted surface

Gearing : Two geartrains with their own energy sources (2 barrels)

Deadbeat seconds : Independent mechanism – Came with 30 teeth on the going geartrain on the secondswheel – Escapewheel on the secondswheel of the independent geartrain

Double lever with jeweled pallets

Winding-setting : Crown with push function to chose between winding or setting

Power reserve : Classic Breguet mechanism by means of a cone moving up and down on the treaded barrel arbor

Displays : Small hours and minutes at 1 o’clock – Large seconds at 7 o’clock – Power reserve winding – setting indicator at 3 o’clock

Casing specifications

Number of components 68 parts

Case Red Gold Au750 5N

Domed sapphire crystal on the front with hard antireflective coating on both sides

Flat sapphire crystal on the back with hard antireflective coating on both sides

Engraving of the individual number in relief

Gold security screws

Polished bezel and center band with hand-finished straight graining

Case dimensions Diameter: 43 mm

Thickness: 12.5 mm

Water resistance 3 atmosphere – 30 meters – 100 feet

Crown Gold with engraved with “G” logo and push to set/wind function

Dial Solid Sterling Silver 925, Frosted surface with diamond cut bevels

Hour- Minutes dial, raised Seconds Dial

Power reserve indicator

Setting-winding indicator

Hands Extended Lancette hands. Flame-blued steel and hand polished centers. Large counter poised seconds hand

Strap Hand-sewn mat brown, alligator leather with Red Gold Au750 5N buckle, engraved with Grönefeld logo

Pour Passion Horlogère : photos live Jacques Olivier, texte Frédéric Dru

Laisser un commentaire